The production process is designed so that the eggs are never touched by hand. Trained personnel is present to operate the fully automated machines and to perform quality control checks.

Each product is identified and recorded using special barcodes to ensure traceability throughout the production and distribution chain, from the raw materials to the final customer.

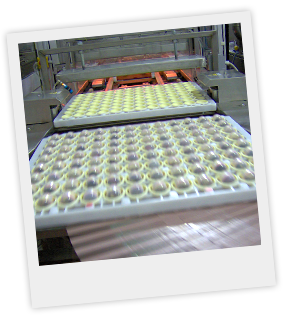

Sweet's production process is quite unique as it uses a cold pressing machine which has been brought to perfection internally.

There are numerous significant advantages of using this type of forming technique over traditional methods:

- Precise control over product weight and uniform thickness of the chocolate shells;

- Perfectly detached surprises without chocolate residues (meaning greater product safety, since the consumer, normally a child, is less likely to put the capsule containing the surprise into his/her mouth);;

- Improved product strength when handled by the consumer;

- An extremely clean and waste-free process;

- Excellent surface finish and more attractive appearance (smooth and shiny surface).

Sweet S.p.A. has a modern air-conditioned warehouse which covers a surface area of 5000 m² , by 12 m in height. It is equipped with a 5-level shelving system. The entire warehouse is mapped and managed by a dedicated software that guarantees real time updating of stock levels and product locations, divided by production lot.

Distribution logistics are provided by refrigerated trucks that maintain the product at a temperature of 18°C from the moment it is loaded until it is delivered to the customer.

> DOWNLOAD THE TECHNICAL DATA